Select a Size

About This Item

InChI

1S/C3H4O2/c1-2-3(4)5/h2H,1H2,(H,4,5)

SMILES string

OC(=O)C=C

InChI key

NIXOWILDQLNWCW-UHFFFAOYSA-N

grade

anhydrous

vapor density

2.5 (vs air)

vapor pressure

4 mmHg ( 20 °C)

assay

99%

form

liquid

autoignition temp.

744 °F

contains

200 ppm MEHQ as inhibitor

expl. lim.

13.7 %

bp

139 °C (lit.)

mp

13 °C (lit.)

density

1.051 g/mL at 25 °C (lit.)

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

Acrylic acid can also be used as:

- A key component in the preparation of copolymer binder, which helps to optimize the performance of lithium-ion batteries.

- A surface modifier for the carbon nanotubes with poly(acrylic acid) in order to improve adhesion and dispersion of the nanotubes in the oxide semiconductor matrix for thin-film transistor applications.

- A reactive monomer for the surface modification of polydimethylsiloxane (PDMS)through a simultaneous polymerization process with ethylene glycol dimethacrylate. Modified PDMS potentially applied in new applications fields such as microfluidics or biomedical devices.

- A precursor for the synthesis of cashew gum/acrylic acid nanoparticles via the copolymerization process. The use of acrylic acid in the synthesis is to introduce hydrophilic functional groups into the cashew gum backbone, thereby improving its solubility in water and increasing its compatibility with other hydrophilic materials.

signalword

Danger

Hazard Classifications

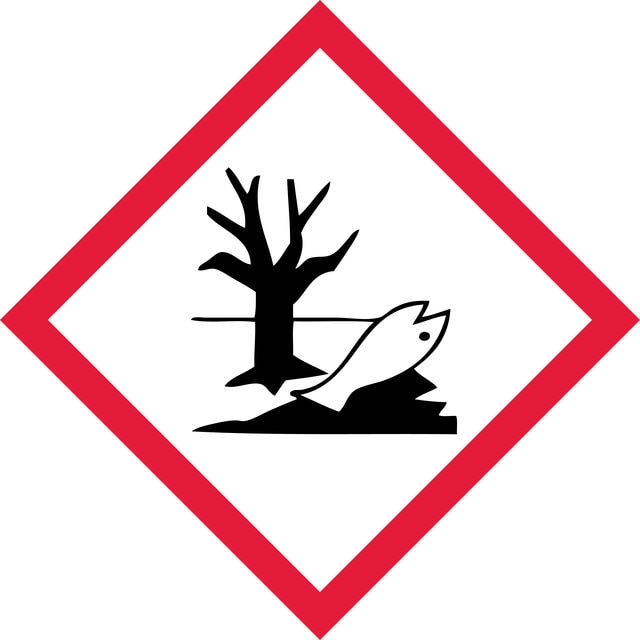

Acute Tox. 4 Dermal - Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Aquatic Acute 1 - Aquatic Chronic 2 - Eye Dam. 1 - Flam. Liq. 3 - Skin Corr. 1A - STOT SE 3

target_organs

Respiratory system

Storage Class

3 - Flammable liquids

wgk

WGK 2

flash_point_f

119.3 °F - closed cup

flash_point_c

48.5 °C - closed cup

ppe

Faceshields, Gloves, Goggles, type ABEK (EN14387) respirator filter

Regulatory Listings

Regulatory Listings are mainly provided for chemical products. Only limited information can be provided here for non-chemical products. No entry means none of the components are listed. It is the user’s obligation to ensure the safe and legal use of the product.

Deleterious substance

pdsc

Class I Designated Chemical Substances

prtr

Group 4: Flammable liquids + Type 2 petroleums + Hazardous rank III + Water soluble liquid

fsl

Substances Subject to be Indicated Names

ishl_indicated

Substances Subject to be Notified Names

ishl_notified

147230-RSAMPLE: + 147230-18KG:4548173105741 + 147230-50KG: + 147230-VAR: + 147230-1L: + 147230-204KG:4548173248387 + 147230-25ML: + 147230-2.5L: + 147230-3KG:4548173105758 + 147230-5ML: + 147230-5G:4548173105772 + 147230-100G:4548173105734 + 147230-500ML: + 147230-BULK: + 147230-500G:4548173105765

jan

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

歯科修復材料の開発は、生体適合性と自然な外観を持つ修復材の必要性から、非常に重要です。アマルガムやコンポジットレジンといった従来の歯科材料には、素材固有の短所があります。

Innovation in dental restorative materials is driven by the need for biocompatible and natural-appearing restoration alternatives. Conventional dental materials like amalgam and composite resins have inherent disadvantages.

RAFT polymerization offers living characteristics to radical polymerization, contributing versatility to reversible deactivation radical polymerization methods.

By altering the physicochemical properties, smart or intelligent drug delivery systems can be designed to deliver therapeutic molecules on-demand. Learn more about the application of stimuli-responsive materials in drug delivery.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service