Select a Size

About This Item

form

dispersion

concentration

2.5 wt. % (crystalline ZnO in 2-propanol)

color

translucent yellowish

particle size

10-15 nm

density

0.800 g/mL at 25 °C

Quality Level

Looking for similar products? Visit Product Comparison Guide

General description

Application

Annealing temperature <100°C.

Other Notes

Post-treatment: Annealing of deposited ZnO films at 80°C - 120°C

Legal Information

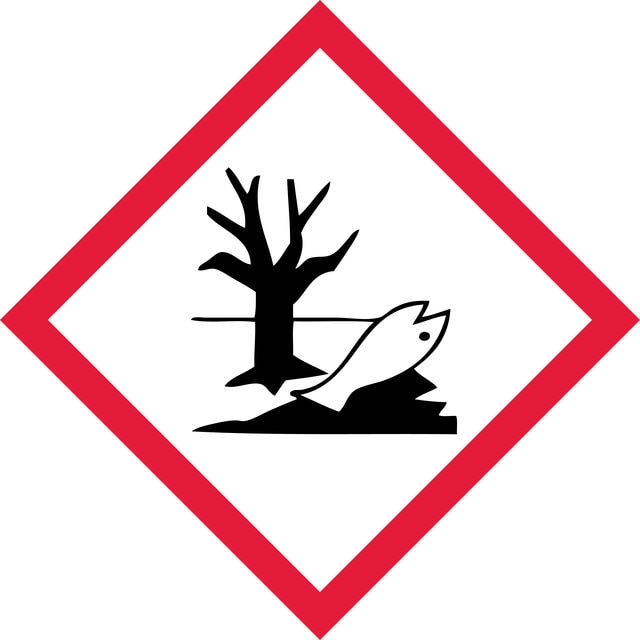

signalword

Danger

hcodes

Hazard Classifications

Aquatic Chronic 2 - Eye Irrit. 2 - Flam. Liq. 2 - STOT SE 3

target_organs

Central nervous system

Storage Class

3 - Flammable liquids

wgk

WGK 1

flash_point_f

53.6 °F

flash_point_c

12 °C

Regulatory Listings

Regulatory Listings are mainly provided for chemical products. Only limited information can be provided here for non-chemical products. No entry means none of the components are listed. It is the user’s obligation to ensure the safe and legal use of the product.

Group 4: Flammable liquids + Alcohols + Hazardous rank II

fsl

Substances Subject to be Indicated Names

ishl_indicated

Substances Subject to be Notified Names

ishl_notified

793361-50ML:4548173354033 + 793361-5ML:4548173340234 + 793361-BULK: + 793361-VAR: + 793361-25ML:4548173340227

jan

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

溶液処理機能性材料の進歩は、産業用および民生用電子機器用の薄膜光電子デバイスにつながる。

時任教授と竹田教授が、フレキシビリティと低コストに重点を置いて、有機エレクトロニクスデバイスのための設計原則と最適化のプロトコルを紹介します。

Avantama製無機ナノインクは、スロットダイコーティングまたはスピンコーティングなどの印刷技術を用いた基板への塗布に用いられます。フレキシブル基板などへの溶液処理による有機太陽電池または有機ELの作製が可能です。

Progress in solution-processed functional materials leads to thin-film optoelectronic devices for industrial and consumer electronics.

Related Content

有機無機ハライドペロブスカイトは、新規光吸収材料として注目されています。ペロブスカイト太陽電池は、塗布による作製が可能なため低コストでの製造が期待され、フレキシブルで軽量な太陽電池の実現に向けた研究が盛んにおこなわれています。

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service